Tracing the evolution of CNC machining from its groundbreaking beginnings to its critical role in today’s high-tech manufacturing industries.

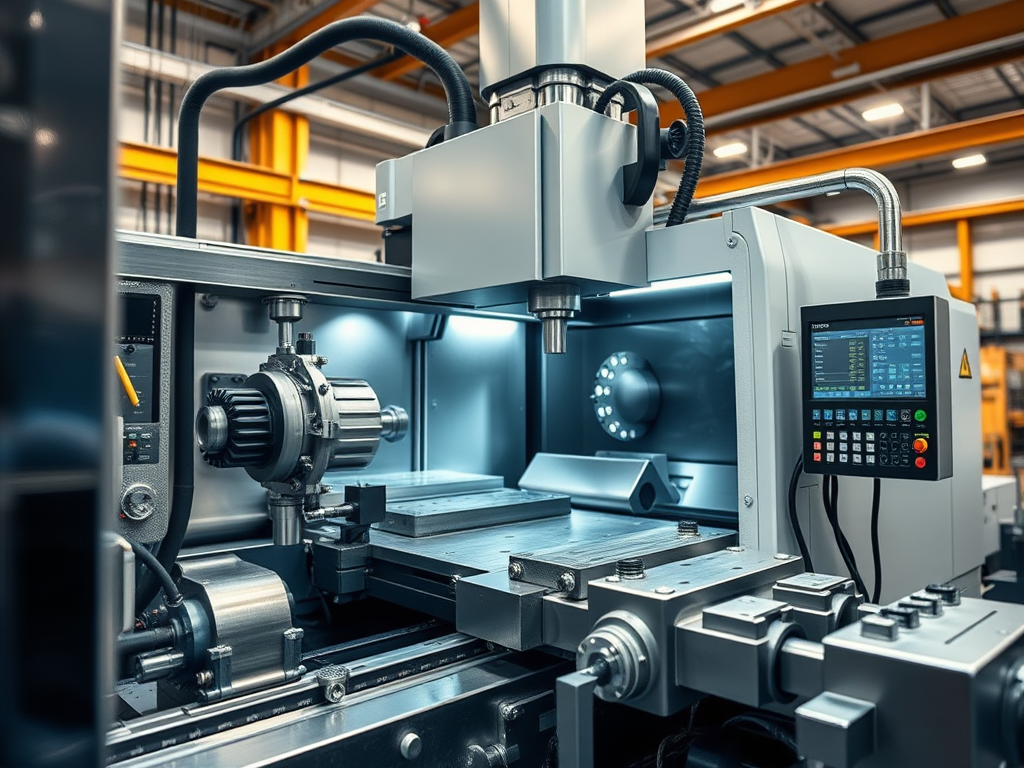

CNC machining has revolutionized how the world manufactures everything from aerospace components to everyday household products. Standing for “Computer Numerical Control,” CNC technology has evolved from rudimentary beginnings to the sophisticated, automated systems we know today. One specific facet — multi-axis machining — has transformed precision manufacturing, opening new frontiers in complexity, efficiency, and design freedom. This article explores the history, modern advancements, and enduring importance of multi-axis CNC machining.

The Early Days: Birth of CNC Machining

The origins of CNC machining lie in the desire to automate manual processes and enhance production accuracy. Early innovators recognized that manual methods were limited by human fatigue and inconsistency. They envisioned a future where machines could be programmed to perform complex tasks with unmatched precision and repeatability.

Manual to Automation

Before CNC, machining was a fully manual process. Skilled machinists operated lathes, mills, and drills by hand, shaping materials with painstaking precision. In 1949, John T. Parsons, an engineer working on helicopter rotor blade manufacturing, pioneered the concept of numerically controlled machines to automate this labor-intensive work.

The First CNC Machine

In collaboration with MIT, Parsons developed the first true NC (Numerical Control) machine — a punched tape-fed milling machine — in the early 1950s. It marked a turning point, showing how computer inputs could control machine movements with remarkable precision.

The Evolution of Multi-Axis CNC Machining

As manufacturing demands grew more complex, CNC technology evolved to offer enhanced flexibility and precision. The transition from basic three-axis operations to multi-axis capabilities marked a major leap forward. This evolution allowed manufacturers to produce increasingly intricate and high-quality parts with fewer manual interventions.

Expanding Capabilities

While early CNC machines operated along three axes (X, Y, and Z), industries soon needed more complex geometries. Enter multi-axis machining, where tools move across additional rotational axes (commonly A, B, and C). 5-axis and even 7-axis machines became vital for:

Creating Intricate Components: Especially important in aerospace and medical industries.

Reducing Setup Times: Machining multiple sides of a part without manual repositioning.

Enhancing Surface Finishes: Continuous tool movement results in smoother, more precise surfaces.

Technological Advancements

Several technological breakthroughs have propelled multi-axis CNC machining forward:

CAD/CAM Integration: Seamless software communication between design and manufacturing.

Real-Time Feedback Systems: Sensors monitor vibrations, temperatures, and tool wear.

Material Innovations: High-performance alloys and composites require advanced machining strategies.

Modern-Day Importance of Multi-Axis CNC Machining

Today, multi-axis CNC machining is indispensable across numerous industries. Its ability to handle complex designs with high precision has made it a cornerstone of modern manufacturing. As product demands continue to grow in complexity and customisation, the importance of this technology only intensifies.

Driving Innovation

From jet engines to orthopedic implants, today’s most groundbreaking products would be impossible without multi-axis CNC machining. Its capabilities enable manufacturers to:

Prototype Faster: Shorten development cycles by rapidly producing test components.

Improve Performance: Produce lightweight, structurally optimised parts.

Expand Design Possibilities: Designers are less constrained by traditional manufacturing limitations.

Industrial Impact

Key sectors leveraging multi-axis CNC machining include:

Aerospace: Precision turbine blades, structural frames.

Medical: Customised prosthetics, surgical instruments.

Automotive: Performance engine parts, custom molds.

Robotics: Lightweight, complex structural components.

A Future Shaped by CNC Innovation

CNC machining continues to evolve alongside advancements in technology and material science. As industries demand greater complexity and precision, multi-axis CNC machining stands ready to meet these challenges and drive the next wave of innovation.

From the earliest NC machines to today’s sophisticated multi-axis marvels, CNC machining has continually pushed the boundaries of what is possible. As materials become more advanced and product designs more ambitious, multi-axis CNC machining will remain at the heart of innovation, empowering industries to achieve greater precision, efficiency, and creativity than ever before.

Keywords: CNC machining, multi-axis CNC, precision manufacturing, CNC history, CAD/CAM, advanced manufacturing, 5-axis machining, automated machining.